To stand out in a crowded marketplace, today’s manufacturers must find ways to optimize their business and pivot in an ever-evolving industry. That’s why many companies are incorporating digital transformation in manufacturing.

The manufacturing industry is currently experiencing a trend known as Industry 4.0, an increase in the use of technology to streamline processes and reach its ideal target market. By incorporating digital elements like automation and artificial intelligence into the workflow, industrial companies are shifting to smart manufacturing, which allows them to scale their business for greater lead generation, revenue growth, and continued success.

Keep reading to learn how digital transformation in manufacturing can boost your business.

Key Takeaways

- Digital transformation in manufacturing is using digital technologies to enhance traditional manufacturing processes.

- When you capitalize on digital transformation, you reduce costs, maximize revenue, deliver a better customer experience, and much more.

- Examples of digital transformation in manufacturing include e-commerce, machine learning, robots, automation, and Internet of Things.

What Exactly Is Digital Transformation?

Digital transformation in manufacturing uses digital technologies, like e-commerce, industrial robots, and automation software, to enhance traditional manufacturing processes. The goal is to:

- Reduce costs

- Improve efficiency

- Maximize revenue

- Improve the quality of products and services

- Deliver a better customer experience

- Adapt easily to changing consumer demands

To achieve digital transformation, manufacturing companies optimize their processes and operations, implement automation and machine learning, gather customer data, then use outside-the-box thinking to create innovative processes and products from the data collected.

The shift toward this digital transformation has been happening gradually over time as technology improves and more consumers (76% of American adults) interact online. But the pandemic caused a need for manufacturing companies to rethink their processes. With face-to-face demonstrations and sales put on hold, industrial businesses had to find a way to adapt and continue to solve consumers’ problems, drive sales, and generate revenue remotely.

The following video further explains Digital Transformation and how it benefits your business:

Source: Yokogawa Industrial Automation via YouTube

5 Examples of Digital Transformation in Manufacturing

Digital transformation can take many forms. Here are five examples of digital transformation in manufacturing.

1. E-commerce

Today’s consumers (and probably most of your competitors) interact online. To stay at the forefront of your audience’s mind, you need to have a digital presence on the internet. Create a website to market and sell your products to buyers. Use SEO basics for manufacturing and industrial companies to earn high SERPs from search engines which, in turn, gain you more visibility. It also helps in driving website traffic for manufacturing companies, so you can deliver valuable information and helpful answers that guide shoppers through the sales pipeline.

Valuable content, obvious call-to-action buttons, contact information, and strong corporate branding are all website must-haves for manufacturing companies. When your website delivers quality information and a positive user experience, you’re likely to raise brand awareness, build brand loyalty, and increase conversion rates for greater success.

2. Machine Learning

Machine learning is a computer’s ability to (artificially) think like a human. Through careful and thorough programming, computers receive large amounts of real-world data to help train them to recall the appropriate responses to various questions and problems. In the world of manufacturing, machine learning typically occurs in one of two instances:

- Supervised machine learning: Machines can identify patterns in data, which is useful for predicting the lifespan of machine parts (based on previous examples) or component failure within a given timeframe.

- Unsupervised machine learning: Identifies its patterns from data sets and delivers answers without predefined outcomes.

Machine learning in manufacturing is especially helpful for predicting when maintenance will occur, evaluating and optimizing processes for greater efficiency, and presenting digital representations of physical products before they’re built.

Machine learning and artificial intelligence can also help you create effective content marketing for manufacturing companies. Using consumer data, you can automatically generate custom content that resonates with and meets the unique needs of your buyers. It saves you time but also helps you craft quality content that generates leads and helps to drive sales.

3. Robots

While robots aren’t overtly new to the manufacturing industry, their technology is constantly evolving and improving, helping them become more useful with greater benefits. Today’s robots connect to more devices, streamline interaction, and work faster and more efficiently for a higher volume of quality products. From heavy lifting and dexterous carrying to managing complex, detailed, and tedious tasks, digital robots reduce the workload of today’s workers so they can focus on other duties that a machine can’t achieve as successfully.

Be sure to mention your state-of-the-art robotics in your brand marketing for manufacturing companies. When buyers see that you’re not only staying ahead of industry trends but are also streamlining your processes so you can better meet the needs of your consumer, they’ll remember your brand and will be more likely to do business with you in the future.

4. Automation

Automation of processes and services enables work without human involvement. Industrial automation handles the production of materials. Control systems handle machinery components to accomplish physical work, like assembling, painting, and packaging. Fixed automation completes a process through programmed commands. Large quantities of materials get done without switching out parts or pieces,

Information gathering and creation are also automatable. Manufacturing companies can send out emails, publish digital content, and connect with consumers at the click of a button. Automation saves time, increases accuracy, and boosts efficiency for higher productivity.

5. Internet of Things

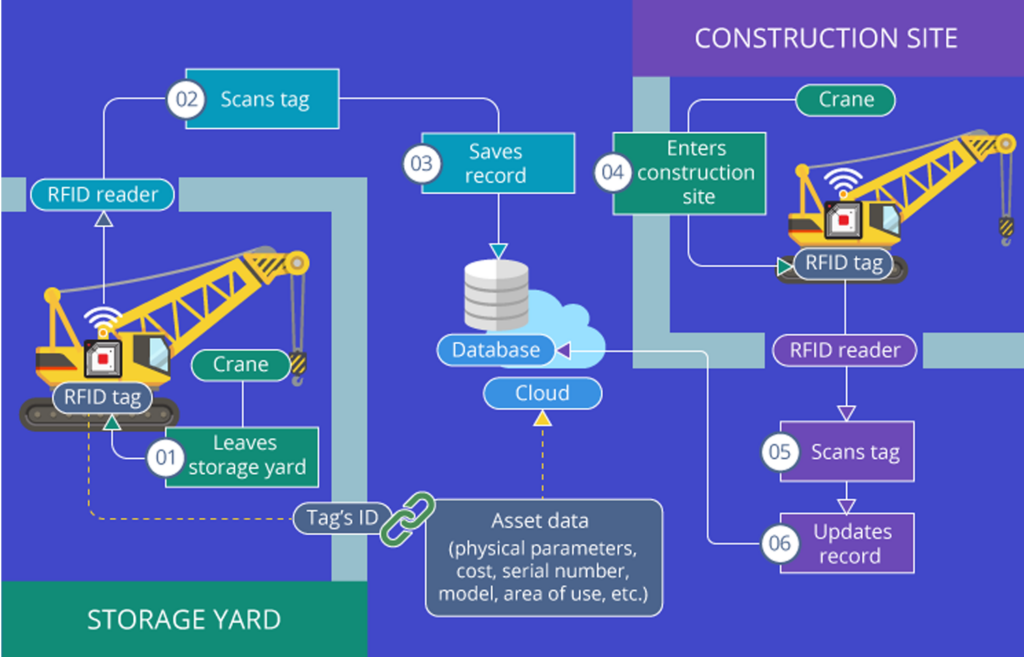

The Internet of Things (IoT) is a huge network of people and things connected to the internet that enables your company to analyze the data collected and shared. When your company and products connect to the IoT, you gain invaluable insights about your business and customers. You can ensure that your marketing for manufacturing is effective and that you’re meeting the needs of your consumers with the best possible solutions.

IoT lets you monitor your equipment remotely so you can see how your machinery is performing and how you can improve your business processes. It also helps you predict maintenance needs to plan repairs and replacements. You can optimize facilities management and provide a better user experience for your buyers.

Maximize Digital Transformation in Manufacturing

Shanahan Strategy follows marketing trends for manufacturing companies to help industrial businesses create digital marketing and sales strategies that attract leads and boost revenue.

Contact Shanahan Strategy today to learn how we can help you maximize digital transformation for optimal results for your business.